| Label :

|

Ed. Kruspe Hrzgl. P.M. Hoflieferant Erfurt |

||||||||

|

Model:

|

Compensating Double |

||||||||

|

Serial Number:

|

None |

||||||||

|

Date of Manufacture:

|

ca. 1910? |

||||||||

|

Key(s):

|

F, B♭, E, and A |

||||||||

|

Valves:

|

4 rotary |

||||||||

|

Bore:

|

|||||||||

|

Bell Flare:

|

|||||||||

|

Bell Throat:

|

|||||||||

|

Bell Diameter:

|

|||||||||

|

Base Metal:

|

Brass |

||||||||

|

Finish:

|

unlacquered |

||||||||

| . (click on photos for larger view) |

|||||||||

|

|

||||||||

|

|||||||||

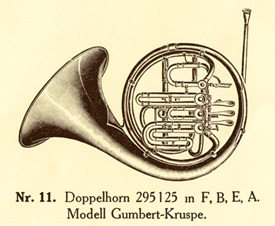

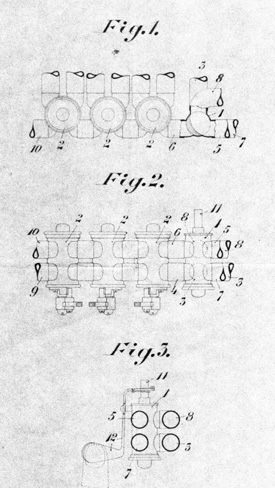

D.R.G.M 232038 change valve (1904) |

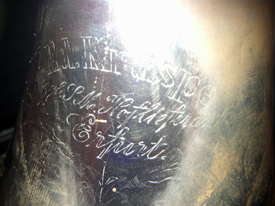

D.R.G.M. 295125 change valve (1906) |

||||||||

As shown above for comparison the two change valves have different geometries to suit the routing of the air path. At left the valve found on Kruspe full double horns ("Fritz", "Horner", et. al.) described in D.R.G.M. 232038. At right the change valve found on Kruspe compensating horns ("Gumpert-Kruspe", "Wendler", et. al.). |

|||||||||