| Label :

|

Made by J.W. York and Sons Grand Rapids Mich. |

|

Model:

|

Single |

|

Serial Number:

|

31546 |

|

Date of Manufacture:

|

1912 |

|

Key(s):

|

F or Eb depending on main slide |

|

Valves:

|

3 Berliner Pistons and 1 tap to select high or low pitch1 |

|

Bore:

|

16.50 mm |

|

Bell Flare:

|

Bell spun separately and "zipper" seamed to bell tail. |

| 7.5 cm. |

|

|

Bell Diameter:

|

29.9 cm. |

|

Base Metal:

|

Brass |

|

Finish:

|

Lacquered |

| . (click on photos for larger view) |

|

|

|

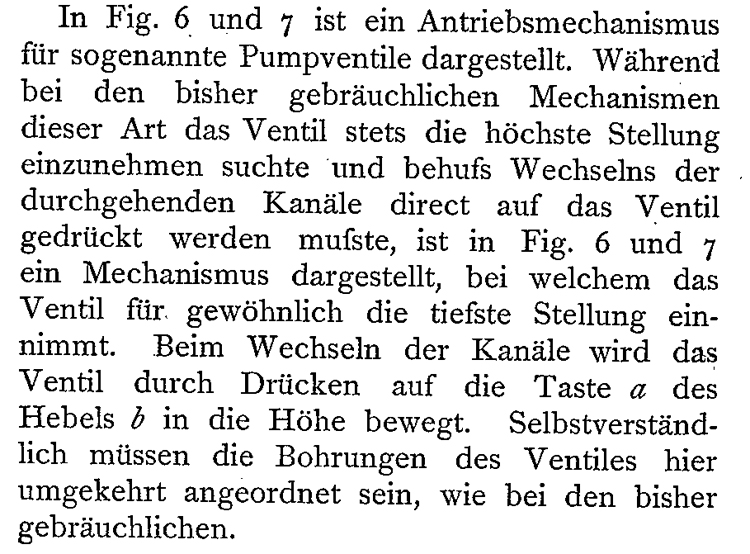

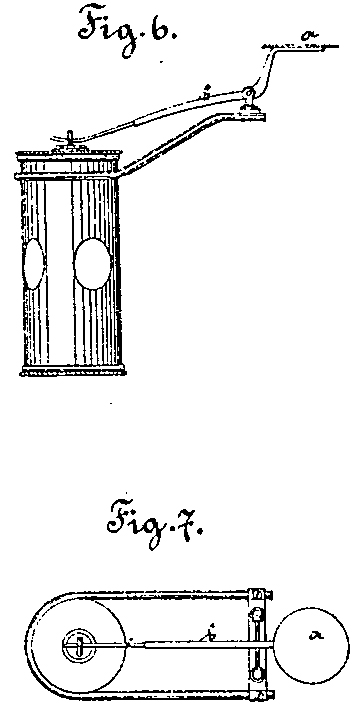

At first glance the instrument shown above might appear to be just another single rotary-valve horn with a stopping valve and a missing valve cap from J.W. York & Sons, Grand Rapids, Michigan. On closer inspection, however, it is clearly a very unusual design. It is tuned to American high pitch (see note 1) and the tap at the top of the valve set is intended to lower it to modern standard pitch. This was common in the early twentieth century when military bands were still performing in the higher pitch. The valve set is actually a version of the Berliner "Pumpen" valves but with rotary-valve-like keys. As can be seen in the photos below the valve levers are connected through slots in the casings to the tops of the pistons which are lifted when the finger keys are depressed. Wire spiral springs (and gravity) return them to the rest position in the usual manner.2 |

|

|

|

|

"Neuerung an Drehventilen für Blasinstrumente" May 6, 1880, C.W. Moritz, Berlin, Patent No. 11511 |

At right a union label is stamped on the casing of the second valve. As best it can be read the letters are "M._.B.P. & S.W.U." although the first two letters are not entirely clear.4 No union with those letters has as yet been identified. The "2" identifies the valve and the York serial number is stamped below identifying the year of manufacture as ca. m1912. No horn of this design has been found in any extant York catalog.5 |

|

|

|